The following is a detailed introduction to the battery energy storage system:

1. Energy Storage Principle

The battery energy storage system stores electrical energy when there is excess electrical energy (such as peak renewable energy generation or grid off-peak period), and releases electrical energy when demand peaks or power is insufficient, thereby achieving energy space-time transfer and supply-demand balance.

2. System Composition

The battery energy storage system is mainly composed of the following parts:

Battery pack: The battery pack is the core component of the energy storage system. It is composed of multiple battery cells connected in series or in parallel to store electrical energy. Common battery types include lithium-ion batteries, lead-acid batteries, sodium-sulfur batteries, flow batteries, etc. Each battery has its specific application scenarios and performance characteristics.

Inverter: The inverter is a device that converts DC power into AC power. In the battery energy storage system, it is used to convert the stored DC power into AC power to supply the grid or specific loads.

Charge and discharge controller: The charge and discharge controller is responsible for managing the charging and discharging process of the battery pack, monitoring the battery's charge and discharge status, current demand, voltage and temperature and other parameters, and controlling the charging current and charging time as needed to ensure the safety, performance and load demand of the battery pack.

Battery Management System (BMS): The battery management system is the intelligent control center of the energy storage system, responsible for monitoring and managing the status and performance of the battery pack. It includes functions such as battery status monitoring, temperature control, battery balancing, fault diagnosis, etc. to ensure the safe, stable and long-life operation of the battery pack.

DC distribution system: The DC distribution system is used to transmit the DC power stored in the battery pack to the load equipment that needs to be powered, including DC switches, current sensors, protection devices, etc., to ensure the safe and stable transmission of DC power.

Auxiliary equipment: Auxiliary equipment includes temperature sensors, humidity sensors, current sensors, etc., which are used to monitor the system's environmental parameters and power parameters to achieve comprehensive monitoring and management of the system.

III. Application fields

Battery energy storage systems can be applied to multiple fields, including:

Power system energy storage: used to balance the peak and valley power of the power system, improve the stability of the power grid, reduce power grid losses, and reduce energy costs. It can also be used as a backup power source.

Transportation energy storage: Applied in electric vehicles, hybrid vehicles, electric bicycles and other transportation vehicles to improve energy efficiency, reduce vehicle exhaust emissions, and improve urban air quality.

Distributed energy storage: Combined with distributed photovoltaic power generation systems, wind power generation systems, etc., to balance energy supply and demand and improve distributed energy utilization.

Electronic equipment energy storage: As a power source for portable electronic devices, such as smartphones, tablets, laptops, etc., it provides long-term power support.

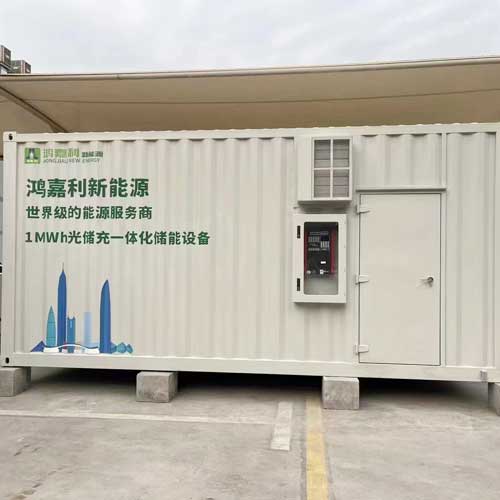

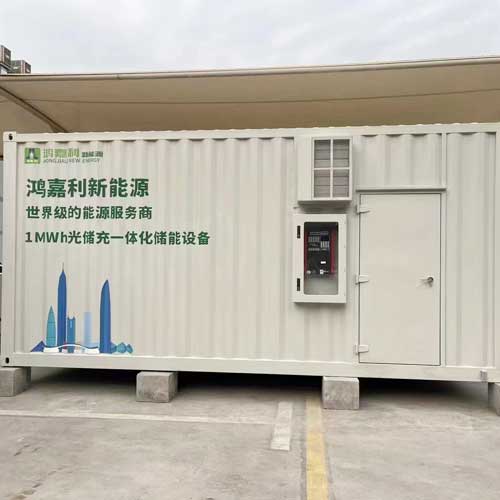

IV. Battery energy storage system project case

+86 18924678741

+86 18924678741 sales@hjlcharger.com

sales@hjlcharger.com Shenzhen City, Guangdong Province, China

Shenzhen City, Guangdong Province, China