Product number | DCB015A-V2G | ||

Detailed specifications | rated power | 15kW | |

charging equipment | Installation method | Wall-mounted | |

route | down in down out | ||

Equipment size | Subject to P/L | ||

Rectification mode | Input voltage range | 260~485VAC | |

Input voltage frequency | 45~65Hz | ||

Output voltage range | 150~750VDC | ||

Maximum output current | 50A | ||

Inverter mode | DC input voltage range | 300~750VDC | |

DC input maximum current | 50A | ||

AC output voltage range | 260~485VAC | ||

AC output frequency | 45Hz-55Hz | ||

cable length | 5m | ||

Measurement accuracy | Level 1 | ||

Electrical indicators | Current limit protection value | ≥110% | |

Voltage regulation accuracy | ≤±0.5% | ||

Steady flow accuracy | ≤±1% | ||

Ripple factor | ≤±1% | ||

efficiency | ≥94.5% | ||

power factor | ≥0.99 (above 50% load) | ||

Harmonic content THD | ≤5% (above 50% load) | ||

feature design | HMI | 7 inch LCD color display touch screen | |

charging mode | Automatic charging/fixed power/fixed amount/fixed time | ||

payment method | Credit card payment/scan code payment | ||

Networking | Ethernet 3G/4G | ||

| safety design | Executive standard | GB/T20234, GB/T18487, GB/T27930, NB/T33008, NB/T33002 | |

security function | Charging gun temperature detection, over voltage protection, under voltage protection, overload protection, short circuit protection, grounding protection, over temperature protection, low temperature protection, insulation monitoring protection, reverse polarity protection, lightning protection, emergency stop protection, leakage protection | ||

Environmental indicators | Operating temperature | -25℃~+55℃ | |

Working humidity | 5%~95% non-condensing cream | ||

working altitude | <2000m | ||

Protection class | IP54 | ||

cooling method | air cooling | ||

noise control | ≤60dB | ||

MTBF | 100,000 hours | ||

Product Attributes

Product Description

Application Scenario

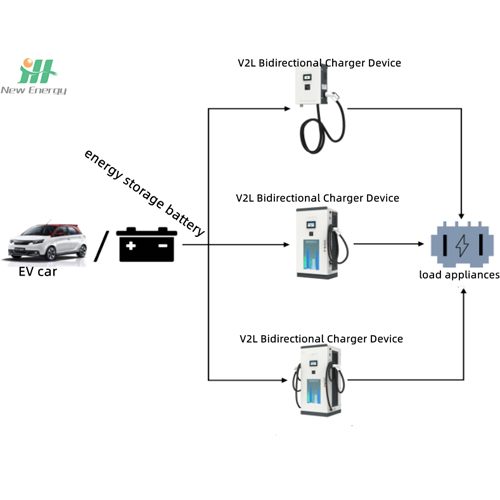

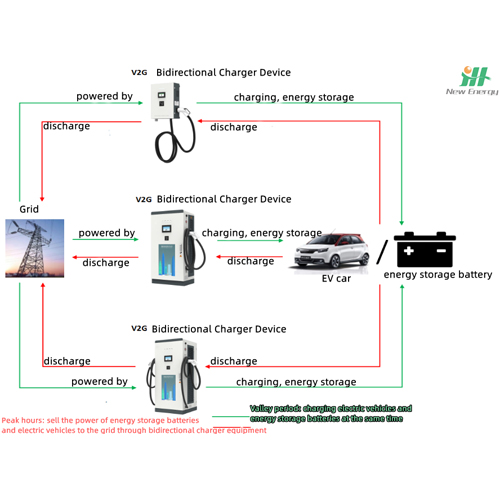

1. Energy storage (electric vehicle energy storage V2G)

It can realize the two-way flow of energy between electric vehicles and the power grid; realize cheap charging of electric vehicles, low-peak electricity, and discharge during peak hours, and the owner can earn the difference in electricity charges; improve load flexibility, reduce distribution network investment, consume clean energy, and boost the electric vehicle industry development and reduce the land occupation of public charging facilities.

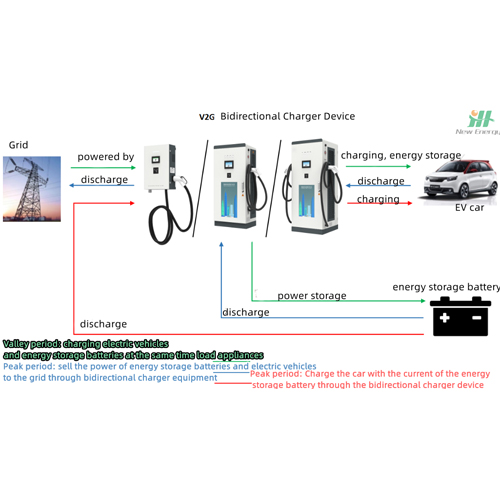

2. Energy storage (battery cascade utilization)

It is suitable for retiring or old power batteries to be used as energy storage. After the isolated AC/DC converter is connected to the battery, it has higher security, higher efficiency, and smaller size; it is integrated with off-grid all-in-one machine, and can be switched to off-grid power supply after the grid is powered off. country, etc.) scenes.

Features

1. Safer and more reliable, more flexible to choose

Full high-frequency isolation design to ensure the safety between the battery and the grid/load;

The internal module adopts full digital control of DSP+CPLD, multi-level software and hardware over-current, over-voltage, over-temperature protection, safe and reliable;

Modular design supports multi-module parallel connection and redundant backup to achieve high reliability.

2. Smaller size

Compared with the traditional two-way power supply scheme, the high-frequency isolation saves the power frequency transformer and is smaller in size.

3. Wide voltage range

Wide grid voltage range and 50/60Hz voltage frequency adaptive capability;

Covering multiple battery voltage levels of passenger cars (100V~750Vdc), the battery voltage range is wide, and it is very suitable for the echelon application of decommissioned power batteries.

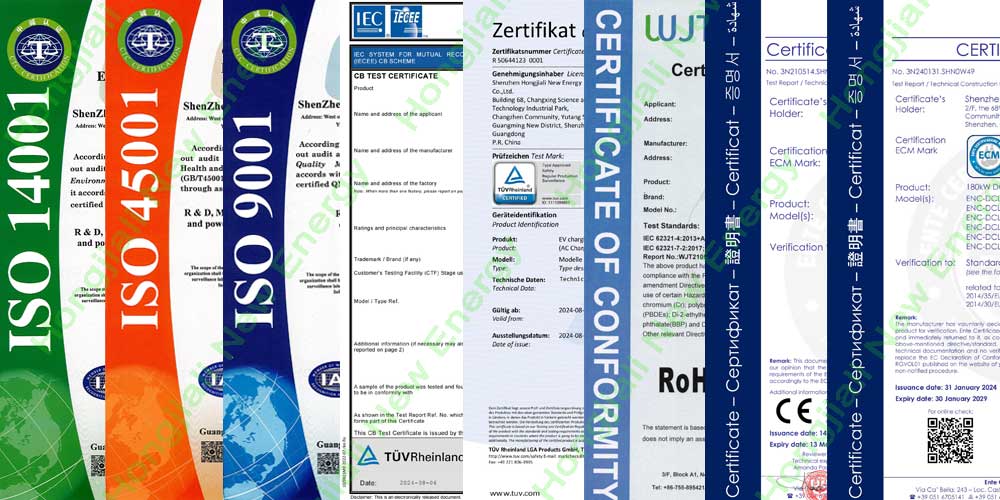

Production Certification

FAQ

Q1: Are you trading company or manufacturer?

A: We are a professional electric car charger manufacturer and source factory.

Q2: what is the lead time?

A: Usually, 15-20 working days to produce.

Q3: Can we ask you to print our logo into chargers? Can the color of the plug and wire be customized according to our requirements?

A: Yes. We support OEM/ODM production.

Q4: How about your product quality? What should I do if something goes wrong?

A: First of all, we sell our products for many years, and we have a professional engineering team in this field. Moreover, our products have been strictly inspected and repeatedly tested before leaving the factory, and the good and good rate of the varieties has reached 99.98%. Finally, we have service providers in some areas, please contact us for more information

Q5: What is your quality control system?

A: Complete all incoming material inspection, process inspection, and final inspection; 30 test procedures will be done before the goods leave the factory, and charging test videos will be sent; products have CE, ROHS, FCC, UL, KC certification.

Q6: Can I install the EV charger by myself?

A: Yes, but we suggest the user contact a professional electrician for installation to avoid potential safety hazards.

Q7:Why my charging power is lower than the specification?e?

A: Because during the charging session, a few factors will influence the output. Here is some potential reason:

①The BMS(Battery management system) of the car controls the charging session. ②The Max allowed current was set and limited through your APP. For more details, please query us at sales@hjlcharger.comQ8: How much time is required to fully charge my car using this charger?

A: The charging speed is determined by three factors working in conjunction: the On Board Charging (OBC) System, the maximum current allowed by the charging cable, and the EVSE. As an illustration, if the EV's maximum allowed power is 30KW and the battery capacity is 60KWh, it would take approximately 2 hours to charge the battery fully.

Q9: What is dynamic load balancing and why do I need that?

A: Dynamic load balancing is a technique that distributes the electrical load across multiple charging stations based on real-time demand. This helps prevent the electrical grid's overload and ensures that each charging station receives appropriate power.

Dynamic load balancing technology can help distribute the available power among multiple EV chargers in real-time, optimizing available power and reducing the risk of overloading the grid. This can help prevent power outages and reduce the need for costly grid upgrades. Additionally, dynamic load Balancing can help reduce charging times and improve the overall charging experience for EV drivers, making it a valuable feature for both residential and commercial charging applications.